Basic insulation

The basic insulation is the insulation of live parts for basic protection against electric shock.

Additional insulation

The Additional Insulation is an independent insulation in addition to the basic insulation. It protects against electric shock if the basic insulation fails.

Double Insulation

The double insulation consists of basic insulation and additional insulation.

Reinforced insulation

Reinforced insulation is a single insulation of live parts that provides the same protection against electric shock as double insulation under the conditions specified in the relevant standards.

Pollution degree 1 (P1)

None or contamination without influence.

Pollution degree 2 (P2)

No conductive contamination, only occasional conductivity due to condensation.

Pollution degree 3 (P3)

Conductive pollution.

Protective separation

Separation between circuits by basic insulation plus additional additional insulation or protective shielding or by an equivalent protective measure (e.g. reinforced insulation)

Body

For the purposes of EN 61558, a body is a general designation for all touchable metal parts, axles, handles, knobs, levers and the like. Also touchable metal fastening screws and metal foils on touchable insulating surfaces.

Protective screen

Separation of hazardous active parts by means of a conductive shield between them, which has a connection for an external protective conductor.

SELV (safety extra-low voltage)

Voltage of a circuit that is separated from the supply network, e.g. by a safety transformer, and the voltage does not exceed 50 V AC or 120 V smoothed DC.

SELV circuit (formerly safety extra-low voltage)

ELV circuit with protective separation from other circuits, without connections for earthing the circuit or the touchable conductive parts.

PELV circuit (functional extra-low voltage with safe separation)

ELV circuit with protective separation from other circuits, which may be earthed for functional reasons and/or whose touchable conductive parts may be earthed.

Protection class I

The protection against electric shock is not only based on a basic insulation but also on an additional earthing terminal for connection to the protective conductor in fixed installations.

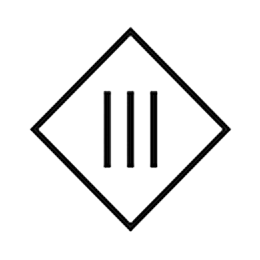

Protection class II

The protection against electric shock is based, in addition to the basic insulation, on a double or reinforced insulation without ground terminal. This makes it independent of the protective measures of the fixed installation. Looped-through protective conductor connections insulated against the transformer are permitted.

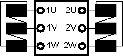

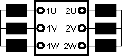

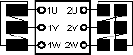

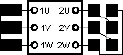

Insulation requirements

The table below lists the minimum insulation requirements for the corresponding protective measures.